Blast-Resistant Buildings

Blast Test

Summary

On August 11, 2020, one arena-style blast test was conducted against:

- 12'x40' anchored on concrete blast-resistant building (BRB)

- 12'x40' unanchored on concrete BRB

- 8'x20' unanchored on the ground BRB

- wooden trailer & job site truck

These units were placed on an arc, around a 6,000-pound ammonium nitrate/fuel oil (ANFO) charge, located 173' from the anchored BRB, and 193 feet from all other specimens. The charge was detonated and each unit’s responses were documented.

Upon inspection following the blast, there were no notable structural damages to any of the RedGuard BRBs, while the wooden trailer had collapsed. Each RedGuard building, as a whole, satisfies the requirements for a LOW DAMAGE LEVEL from the American Society of Civil Engineers’s “Design of Blast-Resistant Buildings in Petrochemical Facilities.”

Among the RedGuard units, there was notable non-structural damage to the flooring and interior finishing work, and the global movement of the structure was minimal.

And now, to the fun details.

Location

STONE OBL Blast Testing Site

Deschutes County, Oregon – 30 miles east of Bend

- 4600 feet from the nearest utility

- 6700 feet from the nearest structure

- 8500 feet from the nearest public roadway

- Accessed via a private road

Buildings

Wooden Trailer & Job Site Truck

12x40 Anchored BRB on Concrete

12x40 Unanchored BRB on Concrete

8x20 Unanchored BRB on Ground

Equipment & Instrumentation

Free-Field Pencil Probes

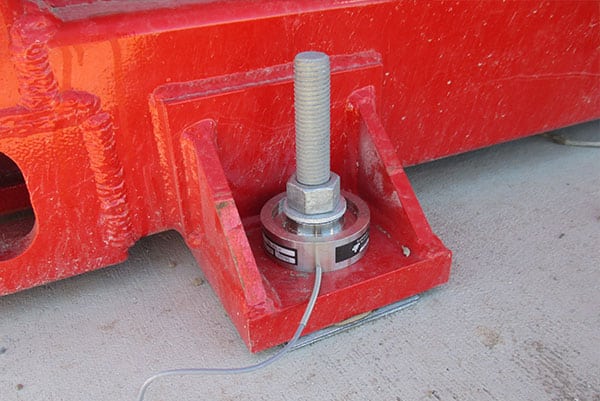

Load Cells

Anthropomorphic Test Dummies (ATDs)

High-Speed Cameras

Pressure Gauges

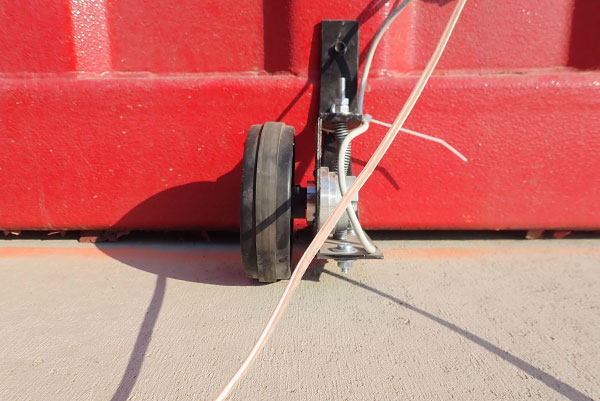

Linear Encoders

Decibel Meters

ANFO (Ammonium Nitrate/Fuel Oil)

Free-Field Pressures

Reflected Pressures

Blast Video

Interior Loop

Conclusion

Stone Engineering concluded that the RedGuard BRBs performed well against the 6,000-lb ANFO charge. The three RedGuard BRBs, each satisfied the requirements for a LOW RESPONSE LEVEL rating, per ASCE designations.

There were no notable structural damages to the Anchored, Unanchored, or Ground Units. There were no notable permanent deformations in structural members, no noticeable cracking in welds, and the anchor plates on the Anchored Unit were wholly intact. The Unanchored Unit slid 1/4-inch toward the blast.

Download the Blast Test PDF

Blast from the Past

Our 2020 test is not our first blast test. In 2007, we performed one of the first field tests for a blast-resistant module when we tested our original design. And then we made the information available to those who requested it. We know that the industry is dynamic, always changing, either in technology or needs. For this reason, we don’t rest on our laurels - we’re always looking for new ways to improve our designs and further the industry.